Offshore Robotics and Automation for Safer Offshore Energy Systems

Status: AWARD END DATE: 08/31/2024

Background:

Robotic Fish-Enabled Pipeline Inspection

Oil pipelines have been deployed in the Gulf of Mexico for decades. After many years of service, the health conditions of those pipelines are unknown. Any leakage from pipes that carry harmful chemical fluids can cause significant pollution to the environment. For example, recently, a pipeline ruptured by a ship anchor, as shown in Fig. 1, in southern California leaks thousands of gallons of oil leakage which causes a despaired environmental disaster to the west coast. If the ruptures are not localized and repair in time, the harm to life, nature, and the economy can be dramatic. Timely inspection of subsea pipelines is thus the key to the prevention of environmental disaster caused by oil spills. Current inspection techniques often involve a trained human operator who operates a remotely controlled vehicle to take images and videos of underwater pipeline for offline rupture detection. Such inspection requires excessive amounts of time and money. With the introduction of state-of-the-art robotic and artificial intelligent technologies, such limitations can be remediated resulting in an extra layer of safety.

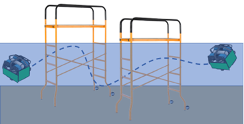

Lifecycle management for underwater assets requires routine sensing. These activities are challenging in deep water environments, and often impossible to track visually due to murky water, when obscured by silt, clay, sand and sediments, or when purposefully trenched (buried pipelines/ trunk lines).For these environments, magnetic sensing is often used to detect ferromagnetic and/or conductive materials [11,12].Because the seafloor is difficult or challenging to access, the magnetic sensors are often mounted on Remotely Operated Vehicles (ROVs). Navigation through 3D structures such as riser platforms or moorings is hard because the sensing required must be in three dimensions, rather than a simple scan of the ground. Moreover, cable management of the tether connecting the ROV to the remote controller becomes increasingly difficult as the number of obstacles increases. The navigation must prevent not only the ROV from collisions with the structure, but also prevent the cable from being entangled. Autonomous Underwater Vehicles (AUVs) reduce the challenges due to tether management but must make navigation choices independently.

Figure 2: Proposed system: an automononous underwater vehicle uses multiple arrays of magnetic sensors to navigate through a set of seal seaffolds.

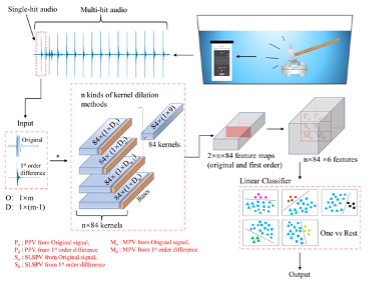

Innovative Research in Monitoring Subsea Connections Using Percussion and Machine Learning

A timely inspection of subsea infrastructure, especially subsea connections, is the key to the prevention of oil spills. Current inspection techniques often involve a trained human operator and require excessive amounts of time and money. The problems are exacerbated if the inspection target is deep underwater. UH researchers developed the innovative percussion approach with machine learning to detecting subsea flange looseness. The main advantage of the percussion approach is the ease for implementation because of the elimination of need of installation sensors on the subsea structures to be inspected. In addition, this approach has the potential to automate the inspection process by integration with remote operated vehicle (ROV) enabled percussion tools.

Figure 3: Flowchart of the proposed FR-MRCKT

Industry Impact

Robotic Fish-Enabled Pipeline Inspection

The research will lead to time-efficient and cost-effective intelligent robotic systems for underwater pipeline inspection. Through this robotic system, pipeline anomalies due to seismic activity, offshore drilling, turbulence, and ship anchoring may be detected at early stages allowing operators to make informed decisions on maintenance and repairs of the pipeline. It is expected that this research will build stronger ties with many companies in offshore energy industry, and will lead to major industrial support. The results of this research will be valuable not only to international deep-water oil and gas markets, but also to subsea renewable energies and subsea mining.

Autonomous Underwater Vehicle Navigation through Steel Scaffolding

This proposal will break new ground in underwater sensing and in robotic navigation by using 3D magnetic sensors to navigate through an underwater environment. As part of the process, this proposal will test two types of terrestrial magnetic sensors for localizing, tracking, and sensing ferrous underwater objects: fluxgate magnetometers and arrays of Hall-effect probes paired with active inductors.

Innovative Research in Monitoring Subsea Connections Using Percussion and Machine Learning

Since flanges are commonly used in subsea oil and gas exploration and production facilities, the proposed research will contribute to the improved level of safe operations of such facilities by providing early warnings of malfunctional flanges. Additionally, with minimum efforts, the proposed research can be extended to other types of connections.

Project Objectives

Robotic Fish-Enabled Pipeline Inspection

The goal of this project is to develop transformative robotic pipeline inspection technology that will lead to a time efficient and cost-effective system for underwater pipeline inspection which can prevent thousands of oil leakage. Such robotic systems will consist of a swarm of bio-inspired autonomous underwater vehicles (BAUVs) equipped with video cameras and underwater communication device with machine learning based image processing and edge computing capabilities. The BAUVs will be able to autonomously swim along a subsea pipeline, detect the ruptures of pipeline, intelligently. Interpret results through unsupervised machine learning and edge computing, and communicate with a nearby station through an underwater communication device.

Autonomous Underwater Vehicle Navigation through Steel Scaffolding

In this project, we propose to explore the design and implementation of a system that uses magnetometers to sense and navigate around magnetic (e.g., metal) structures. Our goal is to produce theoretical and experimental insights towards the use of magnetic sensing and subsea navigation to aid with subsea docking, localization, and repair.

Innovative Research in Monitoring Subsea Connections Using Percussion and Machine Learning

The general goal of this SSI (Subsea Systems Institute) project is to conduct innovative research to improve the percussion method with machine learning for the purpose of monitoring subsea flanges. The specific goals of this project are:

- Develop an innovative approach to monitoring subsea flanges so that the baseline data is no longer needed

- Develop a new machine learning method to increase robustness of the percussion approach.

- To investigate the effectiveness of the percussion approach in monitoring a pipeline with multiple flanges and to determine the least number of needed percussions.

Tasks:

Task 1: Robotic Fish Enabled Pipeline Inspection

- Goal 1: Develop bio-inspired robotic fish for pipeline inspection (80% complete)

- Goal 1.1: Robotic Fish Design (100% complete)

- Goal 1.2: Robotic Fish Fabrication and Testing (100% complete)

- Goal 1.3: Camera Orientation Control (40% complete)

- Goal 2: Develop pipeline tracking control for the robotic fish (60% complete)

- Goal 2.1: Lane Tracking Control (80% complete)

- Goal 2.2: Angle Projection (80% complete)

- Goal 2.3: Image-based Visual Serving (20% complete)

- Goal 3: Develop deep machine learning and vision-based pipeline detection (30% complete)

- Goal 3.1: Underwater Image Restoration (60% complete)

- Goal 3.2: Underwater Video Motion Deblurring (Not started)

- Goal 4: Develop edge computing for limited bandwidth data transmission (20% complete)

- Goal 4.1: Network Development and Optimization (Not started)

- Goal 4.2: FPGA Implementation and Evaluation (Not started)

- Goal 4.3: System Integration (Not started)

- Goal 4.4: Testbed Setup (Not started)

- Goal 4.5: Pool Test (Not started)

Task 2: Magnetic Camera

- Goal 5: Array Sensing and Testing

- Goal 5.1: Single array sensing and testing (100% complete)

- Goal 5.2: Two-panel Array Sensing and Testing (50% complete)

- Goal 5.3 Three-panel Array Sensing and Testing (Not started)

- Goal 6: Fluxgate Sensing

- Goal 6.1: Single axis Fluxgate Sensing (100% complete)

- Goal 6.2: Two-axis Fluxgate Sensing (100% complete)

- Goal 6.3: Three-axis Fluxgate Sensing (90% complete)

- Goal 7: Collision Avoidance & Tracking

- Goal 7.1: Simulation of Control (100% complete)

- Goal 7.2: Integration with Sensing (95% complete)

- Goal 7.3: Hardware Implementation (10% complete)

- Goal 8: High-precision Cable Localization Rig

- Goal 8.1: Analytical Modeling (100% complete)

- Goal 8.2: Dry Land Experiments (60% complete)

- Goal 8.3: Water Experiments (15% complete)

- Goal 8.4: MATLAB Control App (70% complete)

- Goal 8.5: Tension Feedback (45% complete)

- Goal 8.6: Mechanical Design Update (45% complete)

- Goal 9: Material Detection/Classification

- Goal 9.1: Material Detection (40% complete)

- Goal 9.2: Material Classification (25% complete)

Task 3: Monitoring Subsea Flanges

- Goal 10: Innovative Approach to Monitoring (80% complete)

- Goal 11: Deep and Shallow Learning Methods (25% complete)

- Goal 12: Effectiveness of Percussion Approach (50% complete)

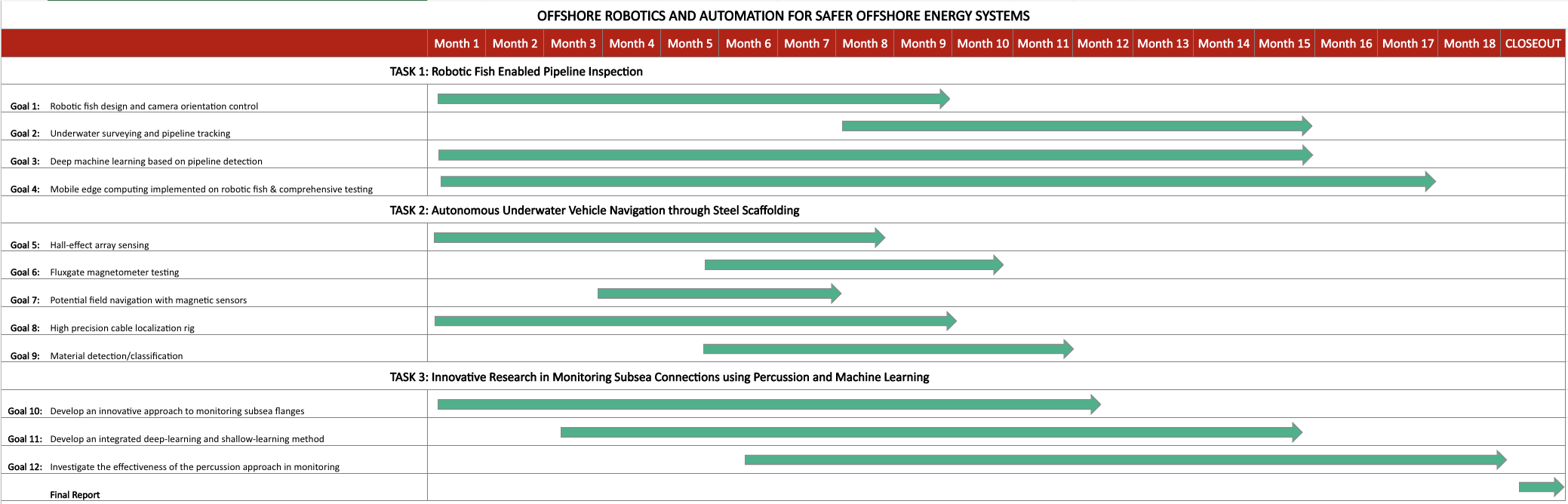

Gantt Chart: